Steam exchanger

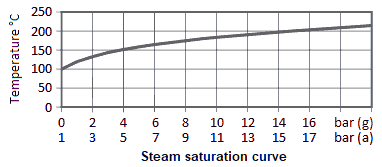

A steam/water system is used to transfer large outputs in industry and in central heating. Superheated steam is used for industrial use (electricity generation, machine drive). Saturated steam is most often used just for heating.

Steam condenses in the steam/water exchanger. Compared to a water/water system, more energy can be transferred to the heated side with a steam/water system and high capacities are achieved. To prevent erosion of the heat exchanger from possible droplets at the inlet to the heat exchanger, heat exchangers with large holes are used. Large openings (SWEP B35TM4, SWEP B427, SWEP B65) reduce the velocity at the exchanger port.

| Capacity | Model | Indicative price w/o VAT |

|---|---|---|

| 50 kW | SWEP B12L | 300 EUR |

| 100 kW | SWEP B35TM4 | 800 EUR |

| 250 kW | SWEP B35TM4 | 1,000 EUR |

| 500 kW | SWEP B427, B65 | 3,000 EUR |

| 1000 kW | SWEP B427, B65 | 4,000 EUR |

| 2000 kW | SWEP B427, B65 | 5,000 EUR |

| 5000 kW | SWEP B427, B65 | 10,000 EUR |

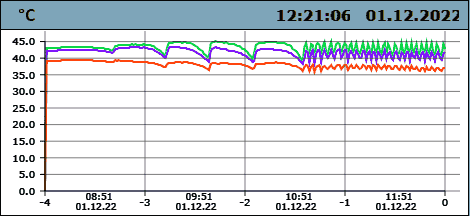

Brazed plate steam exchangers are designed for stable operation, such as heating or charging storage tanks. If the control valve is incorrectly designed (for example, using only 10 % of its range), there will be rapid opening and closing of the flow in an attempt to regulate the system. Large temperature changes then cause material stress, leading to fatigue and damage to the exchanger, significantly shortening its lifespan. Therefore, it is important to ensure that the regulation keeps temperature changes within a limit of 5 K/min.

Steam/water transfer stations

Steam/water exchangers are part of transfer stations and are used to remove heat from the primary circuit (steam) to the circuit of the building (for DHW heating, heating, air conditioning, technology). Domestic hot water is heated in a flow-through manner or can be combined with a hot water tank. Brazed heat exchangers guarantee reliable operation and, thanks to their compact design, transfer stations can be be built with minimal space requirements.

Steam exchanger connection

For sealing threaded pipe joints Uniflon 100% PTFE sealant can be used.

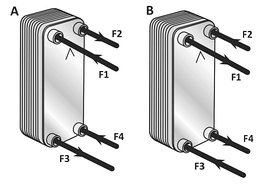

Being connected as a condenser (diagram A): the primary circuit with steam is connected to the internal circuit of exchanger (typically to the left, the exchanger is standing, the arrow points upwards). The steam supply is at the top (F1), the condensate is being drained from the bottom (F3). The heated circuit is connected usually in countercurrent, i.e. inlet at the bottom (F4), outlet at the top (F2).

Never expose the BPHE to excessive pulsations (i.e. cyclic pressure or temperature changes). When starting up the system, open the cold circuit slowly, then slowly open the steam valve. If the input is throttled and the power is set to small, then regulation can cause shocks that reduce the service life of the exchanger.

The steam/water exchanger must not be installed in a network where a flooded control system is used. The heat load is controlled by altering the pressure drop over the valve. We recommend placing a vacuum breaker (aerator) just in front of the heat exchanger. Water droplets at the inlet to the exchanger cause erosion of the distribution channels of the plates. The steam can reach a speed of about 100 m/s and at this speed the condensate droplets act as an abrasive. Therefore, a droplets separator must be placed in front of the control valve. This protects the control valve and the heat exchanger against damage by condensate droplets. If the pressure inside the exchanger is not sufficient to drain the condensate, a condensate pump must be installed.

Condensate must be prevented from collecting in front of and behind the heat exchanger. This can be achieved, for example, by correctly sloping the pipelines. There must be no residual condensate in the heat exchanger. If condensate accumulates, there is a risk of pressure and temperature shocks, especially at low outputs. That reduces the service life of the heat exchanger.

Pohraniční 1280/112

703 00 Ostrava-Vítkovice

Czech Republic

| L | +44 74 9187 2667 |

| E | +44 74 9187 2667 |

| B | info@heat-exchangers.uk |

| sales@heat-exchangers.uk |