Heat exchanger for swimming pools

Heat losses of the pool and the required heating power

In the pool, heat losses occur mainly through evaporation, conduction and radiation. Per 1 m2 of area, a loss is 200 W (indoor) to 1,000 W (outdoor pool). For outdoor pools, quality retention cover will halve the heat loss. Heat loss also depends on the ambient and pool water temperatures.

If the area of the indoor pool is 8 × 3 = 24 m2, then assuming losses of 250 W/m2, a continuous power of 24 × 250 = 6 kW will be needed to maintain the temperature of swimming pool water constant.

At the beginning of the season, more power will be needed to heat the pool up to its operating temperature. If the depth of the pool is 1.5 m, then energy Q = c m ΔT = 4180 × (24 × 1.5 × 1 000) × 1 = 150 MJ is required for increasing temperature by every 1 °C. With a heat source (e.g. heat pump) of 16 kW, the pool increases temperature by every 1 °C in 150 MJ / 16 kW = 9 375 s or 2.6 hours (in fact, it will be slower, as at the same time heat is lost up to 6 kW).

Selecting the right heat exchanger

The heat exchanger capacity cannot be stated by one number in kW: it depends on the designed temperatures.

- Tube heat exchangers are suitable if the heat source is of high temperature. That's why tube heat exchanger manufacturers print exchanger capacity for source of 80 or 90 °C. When connected to a source of 45 or 50 °C, the output transmitted by the tube heat exchanger will be approximately 5 times lower.

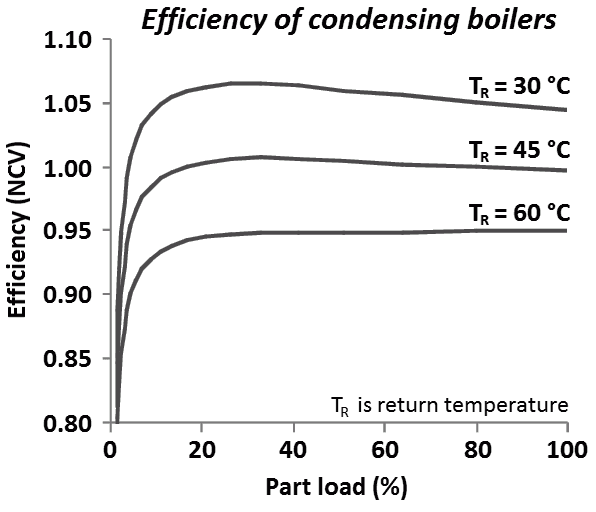

- Both heat pumps and condensing boilers achieve the highest efficiency when operating at lower temperatures (condensing boilers operate with an efficiency higher than 100% if operated at low temperatures). The plate heat exchanger is connected in countercurrent and has a much higher efficiency than the tubular one. The plate heat exchanger is especially suitable where the heat source has a low temperature.

At the beginning, when the water in the pool is cold, the exchanger is more efficient and can transmit twice the output. In domestic applications, an output of about 10 kW is available from sources such as a heat pump, solar panels or a gas boiler. Usually we try to reach temperatures around 29 °C in the pool and calculations are made for such temperatures. The tables below serve for orientation and are shown for common domestic range. We recommend that you request a calculation from us to get the proper size/design determined. We can also supply large exchangers for professional purposes.

Swimming pool exchanger selection

When purchasing a heat exchanger for pool heating, it is necessary to consider what water will be in the pool and choose the material accordingly.

Plain tap water in pool

If the pool water is not cleaned with chlorine and does not contain salt, then it is best to use a compact plate heat exchanger SWEP type water/water. The heat exchanger plates are made of stainless steel AISI 316 and are soldered with copper.

| Heat exchanger performance table (no salt) | |||

|---|---|---|---|

| Source @40 °C | Flow rate | Pressure loss | Model |

| 5 kW | 1 a 2 m3/h | 10 a 25 kPa | SWEP E5Tx20 |

| 5 kW | 1 & 4 m3/h | 2 & 30 kPa | SWEP E5Tx40 |

| 5 kW | 1 & 5 m3/h | 1 & 12 kPa | SWEP B12MTx30 |

| 10 kW | 2 & 3 m3/h | 10 & 25 kPa | SWEP E5Tx30 |

| 10 kW | 2 & 6 m3/h | 2 & 17 kPa | SWEP B12MTx30 |

| 10 kW | 2 & 10 m3/h | 1 & 21 kPa | SWEP B12MTx50 |

| 20 kW | 3 & 15 m3/h | 2 & 35 kPa | SWEP B12MTx60 |

| 20 kW | 3 & 15 m3/h | 2 & 35 kPa | SWEP B12Lx40 |

The pool water can be cleaned, for example, with blue rock. The price of compact SWEP heat exchangers starts at prices around 100 EUR.

Pool water contains chlorine

Free chlorine is often used in concentrations of 0.3 to 0.6 mg/l to disinfect pool water. The free chlorine content should not exceed 1 mg/l (1 ppm). As a by-product of chlorine purification, bound (combined) chlorine is formed. It is undesirable because it is irritating and smells. Bound chlorine should not be present in swimming pools in amounts greater than 0.5 mg/l (0.5 ppm).

The exchangers in the tables are designed for a large flow so that the water in them is heated by 1 to 3 °C. For swimming pool water treated with chlorine, a classic stainless copper brazed exchanger can be used.

A copper brazed heat exchanger cannot be installed for a pool that is salt water or where it is cleaned with oxygen (hydrogen peroxide).

Pool water is salt water (titanium exchanger)

Salt water does not irritate the skin and eyes and does not smell of chlorine. Sea water has a salt content of 3.5 %, the concentration in the swimming pools is chosen to be about 0.4 % or 4 g/l (4000 ppm). Salt (NaCl) is added to pool water mainly when a saltwater chlorinator (salinator) is used. In the chlorinator, an electrolytic reaction occurs, breaking down NaCl into chlorine and sodium. The chlorine then disinfects the water and subsequently recombines with sodium, effectively regenerating the salt. This system keeps the water clean without the need for constant chlorine addition, achieving the desired disinfection and water treatment.

Heat exchangers are commonly made from stainless steel AISI 316, which is resistant to saltwater but not immune. In practice, this means that a standard stainless steel heat exchanger (AISI 304, AISI 316) is not suitable for saltwater. Compact heat exchangers are typically soldered with copper, and copper solder exposed to saltwater corrodes even faster than stainless steel. The higher the temperature, the quicker the corrosion sets in.

For professional saltwater pools, a titanium heat exchanger is chosen. The titanium heat exchanger is more expensive than the same design made of AISI 316 steel. ARES gasketed plate heat exchangers are recommended:

| Heat exchanger performance table (salt water) | |||

|---|---|---|---|

| Source @50 °C | Flow rate | Pressure loss | Model |

| 5 kW | 1 & 2 m3/h | 10 & 35 kPa | A1Sx10 titan |

| 5 kW | 1 & 4 m3/h | 2 & 20 kPa | A1Sx25 titan |

| 10 kW | 2 & 3 m3/h | 10 & 30 kPa | A1Sx15 titan |

| 10 kW | 2 & 6 m3/h | 5 & 30 kPa | A1Sx30 titan |

| 10 kW | 2 & 12 m3/h | 1 & 25 kPa | A2Sx17 titan |

| 20 kW | 3 & 6 m3/h | 10 & 30 kPa | A1Sx30 titan |

| 20 kW | 3 & 12 m3/h | 2 & 25 kPa | A2Sx17 titan |

Titanium tube heat exchangers for salt water

Tube heat exchangers have much less efficiency than plate heat exchangers. However, they also have small pressure losses and are designed for large flows. They are a good choice where there is a high temperature heat source. An example is a solid fuel boiler. These exchangers are not that efficient if connected to heat pumps.

| Heat exchanger performance table (salt water) | |||

|---|---|---|---|

| Heat output | Hot side | Cold side | Type |

| 15–40 kW | 1–2 m3/h (6–15 kPa) |

10–15 m3/h (5–10 kPa) |

Elecro G2 Titanium 30 kW |

| 25–65 kW | 1.5–2.5 m3/h (7–15 kPa) |

15–20 m3/h (8–15 kPa) |

Elecro G2 Titanium 49 kW |

Pohraniční 1280/112

703 00 Ostrava-Vítkovice

Czech Republic

| L | +44 74 9187 2667 |

| E | +44 74 9187 2667 |

| B | info@heat-exchangers.uk |

| sales@heat-exchangers.uk |