Gasketed plate heat exchangers ARES and Alfa Laval

Design

Gasketed plate heat exchangers are composed of thin corrugated steel plates, which form channel spaces for media. There are also gaskets between the plates and the plate pack is stacked into a frame and compressed by tightening bolts together. This achieves high rigidity with high thermal conductivity.

Plates material

The material of the plates is chosen with regard to the media used and the temperatures. Even drinking water can be aggressive towards stainless steel if it contains, for example, chlorides. The higher the temperature, the more corrosive are the effects.

AISI 316L stainless steel is used as standard in the production of heat exchangers. If the presence of chlorides and fluorides can be ruled out, a cheaper design from AISI 304L stainless steel can be considered. The plates can also be made of steel with a higher addition of molybdenum (Mo-steel 254 SMO): they then have a higher resistance to both chlorides and some chemicals. Alternatively titanium steel.

Types of gaskets

EPDM max. temperature 140–160 °C ![]()

EPDM S max. temperature 170–190 °C ![]()

NBR max. temperature 120–140 °C

VITON max. temperature 180–200 °C

For aggressive media, a special material is selected, for example:

- Sulfuric Acid (H2SO4): The exchanger is made from C276 steel + FKM/Viton seal. At low temperatures and for lesser concentrations, chemical reactions occur slowly: AISI 316 steel + EPDM gaskets are sufficient.

- Hydrochloric Acid (HCl): The exchanger is manufactured from C276 steel + FKM/Viton gaskets. For low concentrations, AISI 316 steel is adequate.

- Sodium Hydroxide (NaOH): For normal temperatures, use AISI 316 or preferably AISI 316L; you may select a "all-stainless steel" exchanger. For higher temperatures and concentrations: steels with high nickel and molybdenum content (C-276, 904L) + EPDM gaskets.

- Mineral Oils: In most cases, a standard copper-brazed exchanger is suitable. Alternatively, a gasketed exchanger made from AISI 304/316 steel + NBR gaskets can be used.

- Salt Water (Sea Water): Stainless steel AISI 304/316 corrodes in salt water. Titanium steel + NBR or EPDM gaskets must be used.

- Distilled, Demineralised Water: Also referred to as "hungry." Copper-brazed exchangers should be avoided as copper gradually dissolves in hungry water. Similarly, for water with hydrogen peroxide or otherwise rich in oxygen. For these instances, a full stainless exchanger (AISI 316) is usually selected.

Design pressures

Plate and frame heat exchangers are manufactured for various pressures: low up to 10 bar, medium pressures PN16, PN25.

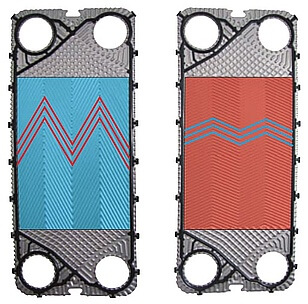

Corrugation patterns

Common channel shapes are L, M and H. L channels are suitable where low pressure losses are required. Plate heat exchangers with H channels have a high transfer capacity; a high approximation of the temperatures of the primary and secondary circuit is achieved.

Standard connections

There are choices for connection to the plate heat exchanger. The exchangers are mostly equipped with external threads for small exchangers and flanges for larger ones.

Calculation and design of heat exchangers

We will design a suitable type of heat exchanger for your project. We just need to enter the expected operating values into our system (heat exchanger capacity, inlet and outlet temperatures or flow volumes, or the required max. pressure drops) to determine the best design for you.

| Sondex | ARES | Reflex Longtherm | Port dist. [mm] |

|---|---|---|---|

| Danfoss S4A | A1S | RHG-04 , RMG-04, RLG-04 |

70 × 381 |

| Danfoss S8A | A1L | RHG-08 , RMG-08, RLG-08 |

70 × 656 |

| Danfoss S7A | A2S | RHG-07 , RMG-07, RLG-07 |

126 × 394 |

| Danfoss S14A | A2M | RHG-14 , RMG-14, RLG-14 |

126 × 694 |

| Danfoss S20A | A2L | RHG-20 , RMG-20, RLG-20 |

126 × 894 |

| Danfoss S9A | A3S | 192 × 380 | |

| Danfoss S19A | A3M | RHG-19 , RMG-19, RLG-19 |

192 × 700 |

| Danfoss S31A | A3L | 192 × 1050 | |

| Danfoss S22 | A4A | 225 × 719 | |

| Danfoss S21A | A4S | RHG-21 , RMG-21, RLG-21 |

225 × 719 |

| Danfoss S47 | A4M | RHG-51 , RMG-51, RLG-51 |

225 × 1365 |

| Danfoss S41A | A6S | 296 × 890 | |

| Danfoss S62 | A6M | 296 × 1292 | |

| Danfoss S86 | A6L | 296 × 1694 | |

| Danfoss S65 | A8M | 395 × 1091 | |

| Danfoss S100 | A8L | 395 × 1489 |

We supply Sondex (Hang-On) plates and gaskets for Danfoss, Reflex Longtherm heat exchangers.

Capacity overview for gasketed plate heat exchangers

Indicative capacity overview of outputs for gasketed ARES heat exchangers is for inlet/outlet temepratures circuit and 75/85 °C secondary circuit. We will prepare the exact calculation of the required heat exchanger size on request, please email us your needs for a quote. Approximate prices are in the price list of heat exchangers.

| Capacity | ARES | Danfoss | Flow rate | Pres. loss |

|---|---|---|---|---|

| 50 kW | A1L x 30 | S8A-IT10-30 | 4.4 m3/h | 20 kPa |

| 100 kW | A1L x 50 | S8A-IT10-50 | 8.8 m3/h | 30 kPa |

| 200 kW | A3M x 25 | S19A-IG16-25 | 18 m3/h | 30 kPa |

| 500 kW | A3M x 60 | S19A-IG16-60 | 44 m3/h | 40 kPa |

| 1 000 kW | A4S x 100 | S21A-IS16-100 | 88 m3/h | 50 kPa |

| 2 000 kW | A6S x 120 | S41A-IS16-120 | 180 m3/h | 50 kPa |

Plate heat exchanger applications

Gasketed exchangers are suitable

- for normal use instead of brazed heat exchangers, if the exchanger needs to be disassembled for cleaning;

- where it is necessary to have an option to expand the exchanger with additional plates;

- in industrial applications such as oil coolers or water coolers;

- for higher capacities (over 500 kW);

- for aggressive water/media;

- for pool heating (these exchangers do not contain copper brazing, which corrodes in chlorinated water).

The installation and operation manual can be downloaded here.

Pohraniční 1280/112

703 00 Ostrava-Vítkovice

Czech Republic

| L | +44 74 9187 2667 |

| E | +44 74 9187 2667 |

| B | info@heat-exchangers.uk |

| sales@heat-exchangers.uk |