Plate wort chiller

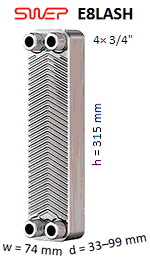

Plate chiller SWEP E8LASH

The SWEP E8LASH plate chiller is extremely effective for rapid cooling of hot wort. Compared to a conventional heat exchanger, E8LASH has narrower channels and is asymmetric. Therefore, it has much greater efficiency (but also greater pressure losses). When chilling the wort, small flow rates are used therefore, pressure losses are not an obstacle. The table demonstrates the efficiency of the asymmetric exchanger SWEP E8LASH compared to the classic design (e.g. SWEP E8TH or exchanger from a different manufacturer). Performance is shown for flows of 200 l/h on both circuits (wort 90 °C, cold water 2 °C):

| Conventional exchanger | Asymmetric narrow | ||

|---|---|---|---|

| Model | E8Tx40 | E8LASx20 | E8LASx40 |

| Plates count | 40 | 20 | 40 |

| Depth | 94 mm | 33 mm | 59 mm |

| Wort | 90/14.7 °C | 90/13.8 °C | 90/10.0 °C |

These coolers have small pressure losses and can therefore be used without a pump (by gravity). However, pump pressure is desirable for cleaning. This chiller is made of stainless steel AISI 316 with copper brazing.

Temperatures

Beer production technology requires the chilling of hot wort from a temperature of about 90 °C to a temperature of about 7 °C. There are several methods and this is usually achieved by cooling with ice water in a plate chiller (exchanger). The ice water is counter-heated to approx. 80 °C and that returned heat can be used elsewhere for optimum efficiency.

Economics of operation and quality of wort

The choice of exchanger affects the economy and the quality of the beer produced. The wort can be chilled by a small exchanger, but a large amount of ice water will be needed. In the long run, it is more economical to purchase a more efficient exchanger and thus have less ice water consumption.

Chiller selection

- A more efficient chiller consumes less cooling water (the water heats up to a higher temperature).

- The more efficient chiller cools the wort faster. This prevents oxidation and contamination of the wort. Although most microorganisms are killed by high temperatures, oxidation degrades the wort. During heating, dimethyl sulphide (DMS) is formed and evaporated. Dimethyl sulphide is formed even after heating before complete cooling and gives an unpleasant aroma to the product. Slow cooling also makes beer cloudy. Once the batch of wort is ready, the goal is to cool it as quickly as possible (within an hour at the latest, preferably within half an hour).

In the table below are shown recommended coolers for cooling at rate of . To prevent fouling and particle trapping in the channels of plate cooler, it is important not to select too many plates. Increasing the number of plates has a similar effect to lowering the flow rate, as it divides the media over more channels, reducing the flow in each specific channel. This can result in particles becoming trapped within the channels (fouling). The table shows the recommended wort flow rates on the given exchangers. A 100 liter batch should be cooled in about 30 minutes with an E8LASHx20 cooler. A batch of 50 liters in 15 minutes on the same cooler, etc.

| Beer wort 1000 l/h, chiller SWEP B85Hx50 | |||

|---|---|---|---|

| Beer wort 90 °C | 1000 l/h | 1000 l/h | 1000 l/h |

| 90/19.4 °C | 90/14.4 °C | 90/12.3 °C | |

| Water 10 °C | 1000 l/h | 1250 l/h | 1500 l/h |

| 10/78.2 °C | 10/68.4 °C | 10/60.0 °C | |

| Pressure drop | 2 & 2 kPa | 2 & 3 kPa | 2 & 4 kPa |

Information, installation and cleaning

- The name of the heat exchanger model above consists of the heat exchanger version and the number of plates (e.g. "x20" indicates 20 plates).

- The pressure drop is shown in the order wort, cooling water; 10 kPa corresponds to 1 meter of water column. Pressure losses are lower if the heat exchanger has more plates. Pressure losses are also lower if the media flow is lower.

- Our chillers have external threading connections. Small exchangers have ISO G 3/4", larger ones have 1".

- The data above is for illustration purposes and we recommend that you have the calculation performed by us for optimum results.

- Even stainless steel corrodes in adverse environments. All our coolers are made of stainless steel AISI 316, which is more durable than AISI 304. We also offer all-stainless steel chillers (these do not contain copper solder) and gasketed chillers (can be disassembled and cleaned).

- Once cooling is complete, place the chiller into clean water. Before cleaning, first rinse it with a stream of warm water.

- The exchanger should be cleaned with the current in the opposite direction to that which is normal during operation. Stop and restart the supply to get any dirt released. The E8LASH heat exchanger is designed for pressures of 10 bar, the B85 series is designed for much higher pressures. At high flow rates (approximately 1 m3/h) there is a turbulent flow between the exchanger plates. That increases the cleaning effect. Use a circulation pump for cleaning the unit.

- A 2.5% solution of sodium hydroxide (NaOH) is used for cleaning biological deposits. This solution can corrode both stainless steel and copper, which is used to braze the plates. When using this chemical, it is necessary to clean the heat exchanger quickly. Corrosion accelerates at higher temperatures. From the perspective of resistance to NaOH, it would be more suitable to use a fully stainless steel heat exchanger (without copper brazing). However, such a solution is approximately three times more expensive, and the available fully stainless steel heat exchangers do not achieve the same high cooling efficiency.

- Clean the scale only if you have indications that the exchanger is clogged. A solution of nitric or phosphoric acid is suitable for descaling. Finally, the acid has to be neutralized by 1-2% sodium hydroxide solution (NaOH) or sodium bicarbonate solution (NaHCO3). Plate brazed heat exchangers use copper to braze each plate together. Stronger acids corrode copper, use acids in concentrations up to 5 %. Corrosion develops faster at higher temperatures.

- Let you also search for and use PBW cleaner (Powdered Brewery Wash), it combines sodium metasilicate with the percarbonate.

- Temperatures around 80 °C destroy most microorganisms and are used for disinfection.

Chiller installation

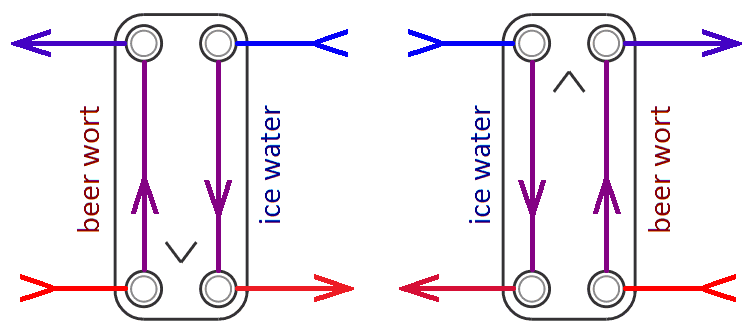

The chiller is connected so that both circuits flow against each other (countercurrent connection).

It is advisable to bring the wort to the lower inlet, then "geyser" continuously washes away particles from the channels of the exchanger. The SWEP E8LASH exchanger has an asymmetrical channel arrangement: the inner circuit has narrower channels than the outer one. Connect the wort to the outer circuit so the dirt can pass through wider ducts. Also, the outer circuit is adjacent to the surrounding space and cooling will also take place on the front and rear plate (these are in contact with the air).

Two-stage chiller

Another option is two-stage cooling. In this case, two exchangers are needed. In the first one, the wort is cooled to 15 to 20 °C using water from a well or tap. The cooled wort is chilled with ice water in a second exchanger to the desired temperature of about 7 °C. This reduces ice water consumption. However, the whole device is more complex and has higher maintenance requirements.

Pohraniční 1280/112

703 00 Ostrava-Vítkovice

Czech Republic

| L | +44 74 9187 2667 |

| E | +44 74 9187 2667 |

| B | info@heat-exchangers.uk |

| sales@heat-exchangers.uk |